Background

The Ardersier Fabrication Yard was built on a tidal flat area of coastline which lies on the southern shore of the inner Moray Firth between Nairn and Fort George. From 1973 to 2000, thousands of people worked there, fabricating over half a million tonnes of structures for the offshore oil and gas industry. The Yard was established by a Louisiana based company “McDermott” which specialised in the fabrication and installation of offshore oil and gas platforms.

In 1947 McDermott installed the first steel platform offshore in the shallow waters of the Gulf of Mexico and subsequently expanded its platform fabrication activities internationally. During the 1960s and early 1970s, exploration drilling in the North Sea revealed significant oil and gas reserves that, if developed, would necessitate UK-based platform fabrication facilities. Recognising this demand, McDermott sought to establish a fabrication business in the UK. By 1973, a combination of political tensions in the Middle East, oil embargoes and the UK’s strained public finances hastened the North Sea development programmes to secure stable energy supplies.

Fabrication Yard Selection

McDermott’s search for a suitable site to establish a fabrication yard led them to a particular area known as the Carse of Ardersier. This site was selected as an ideal location, offering sheltered waters with direct access and proximity to the North Sea. Notably, the local area had a substantial population that could provide a workforce. The site was acquired from Cawdor Estates in early 1972, and McDermott Scotland commenced operations in June of that year.

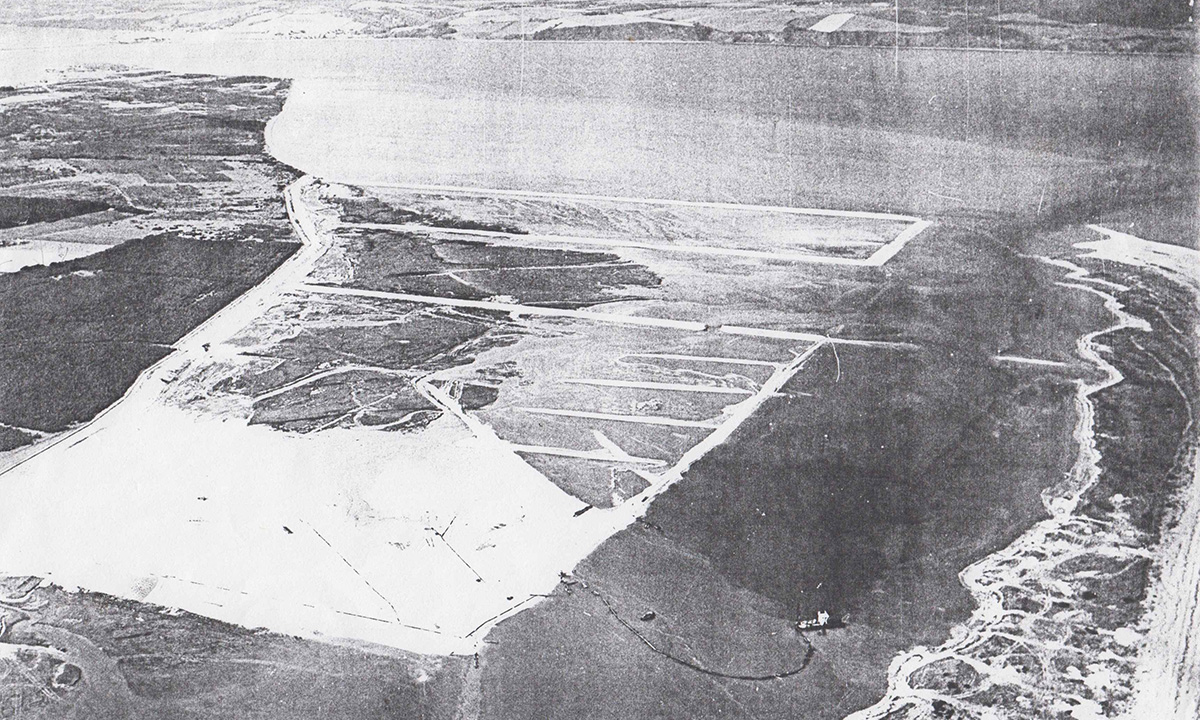

Establishing The Yard

The yard was constructed on an area of tidal salt marsh using silt material dredged from the adjacent natural inlet to create a navigable channel between the shore and the sandbar.

With the reclaimed land stabilised and the sheet pile wall forming the quayside being established construction of the Yard facilities commenced. By early 1973, trades training schools had been established and staff recruitment was underway.

Yard Facilities and Operations

Once fully developed, the Yard occupied a 325-hectare site, featuring a 1.1 km long quayside along its northeastern boundary and a navigable channel leading to the open sea. The Yard facilities comprised storage areas, pre-fabrication shops, two pipe mills, assembly buildings and two jacket slipways. The total covered area of the shops and assembly buildings measured 65,000 m², equivalent to 10 football pitches. The slipways could accommodate the assembly and loadout of jackets weighing up to 30,000 tonnes. A substantial fleet of high-capacity crawler cranes, forklifts, and trailers facilitated the assembly of platform structures, with the largest crane capable of lifting 1,350 tonnes.

The initial strategy for yard operations was to establish a self-sufficient facility capable of managing all aspects of constructing offshore structures. As time progressed, a local supply chain emerged, allowing the business to efficiently outsource specific services.

In the mid-1980s, further investment was made in the Yard facilities, which included a new Pipemill, Pile Handling Facility, Girder Shop, Profile-Cutting Shop, Pipeshop and an Automated Warehouse. A pipeline Spool Base facility and a dedicated quay was constructed in 1994.

The Facilities page within this website contains images and a description of activities carried out in the various buildings and areas within the Yard.

The Area and the People

Before the development of the North Sea oil and gas fields, the inhabitants of the Moray Firth area primarily engaged in farming, fishing, forestry, and tourism. Establishing a fabrication facility in a community without a strong engineering foundation posed a notable challenge in building a skilled workforce. A comprehensive recruitment and training initiative was launched to educate workers in metal fabrication, welding, and related trades to address this issue. Hundreds of recruits underwent rigorous training and testing, with staff and supervision from other McDermott facilities providing on-the-job training. The high demand for North Sea platforms resulted in a steady stream of orders throughout the 1970s, significantly expanding the workforce enabled to a large extent, by the training programme. McDermott Scotland received its first contract to fabricate structures for the Phillips Ekofisk field in Norwegian waters.

The establishment of the yard transformed various aspects of the local economy. Many workers moved to the area with their families and settled permanently, thereby increasing the demand for housing and education.

The local supply chain, set up to support yard operations, allowed numerous local service companies to flourish and expand both nationally and internationally.

Training School

The onsite training school catered to welders and fabricators. Intensive courses were provided for recruits who may have had no previous experience in metal fabrication. The training goal was to elevate them to a level of competence where they could work productively within yard operations. Subsequent on-the-job testing would elevate the tradesman to a top rate of pay.

The Workforce

The optimum staffing level was 1,200 tradespersons, generating 2 million productive hours annually. In practice, staffing levels often significantly exceeded this number, and the consequential strain on resources lead to inefficiencies which had a negative impact upon productivity. Given the scale of investment in offshore development projects and the timescales in which they required to be executed, many projects were schedule-driven at the expense of efficiency.

Work Patterns

A standard workweek in the Yard consisted of 50 hours across five shifts of 10 hours each. When required, night shifts were carried out over four shifts of 12 hours each. Weekend working also was used on a selective basis where time constraints required critical activities to be performed out with the standard work patterns.

A rota system of three shifts over 24 hours was introduced briefly in the 1980s. This shift pattern was not popular with the workforce and was judged to be inefficient. As a consequence, the two-shift system was reinstated.

Site Welfare

Numerous canteens were located across the Yard with facilities for hot food for all employees.

A well-staffed medical surgical unit was located onsite, where highly trained nurses offered first aid to anyone injured. These nurses were particularly adept at treating eye injuries, which were common due to the nature of the work and the environment.

Trade Union Agreement

Prior to opening the Ardersier Yard for construction, McDermott signed an agreement with the AUEW (Amalgamated Union of Engineering Workers) and the EETPU (Electrical, Electronics, Telecommunications, and Plumbing Union) to cover all hourly-paid workers. Membership of the trade union was mandatory from the first day of employment. The AUEW changed its name to the AEU (Amalgamated Engineering Union) in 1986 and later merged with the EETPU in 1992 to form the AEEU (Amalgamated Engineering and Electrical Union). The Yard operated under a single trade union agreement throughout its existence, and although there were occasional disputes, industrial relations were generally considered to be good.

Before arriving in Ardersier, McDermott had limited experience working with trade unions. They had valid concerns about having multiple trade unions on site, considering the potential for demarcation issues and inter-union disputes, as several unions represent the diverse skills required in oil and gas construction.

The agreement was seen as better aligned with complete flexibility in working practices to maximise productivity and prevent workflow interruptions. The union negotiators regarded it as a very forward-thinking and progressive approach. On the first day of employment, hourly-paid employees joined the trade union and participated in induction at the Training School, where all the conditions were outlined.

A significant employment benefit was the mandatory final salary pension scheme, which was unique in the construction industry at that time. The company also offered a high level of training, which benefitted employees later in their careers.

A Cyclical Business

The demand for offshore structures was dependent upon the pace of discovery and development of offshore fields in the North Sea to sustain the fabrication business on the Yard. Such developments were sensitive to a number factors such as oil price, taxation regimes, political considerations, etc, which combined to create peaks and troughs in demand. This became a common feature of the business which continued throughout the history of the Yard, with the most noticeable effect being the fluctuating requirement for labour and resources. The Yard entered its busiest period in the 1980s, when several large jacket structures and the Hutton TLP Topsides were constructed, leading to employee numbers peaking at around 4,500. After this period the workload continued in its cyclical manner with rising and falling employee numbers. Following a busy period from 1991 to 1992, work dried up completely, and the workforce was reduced to fewer than 50.

The BarMac Era

In early 1995, McDermott Scotland established a joint venture with Brown & Root Highlands Fabricators, the owners of the Nigg fabrication yard and long-standing competitors. The Nigg yard encountered challenges similar to those faced by Ardersier in securing work. The owners of the respective facilities, both prominent international contractors, believed that the combined strengths of the two yards would perform better in the shrinking market. Thus, BarMac was launched.

BarMac enjoyed six productive years of work, achieved through the influence of their respective parent organisations and the capabilities of their combined facilities. However, by the end of 2000, the demand for fabrication of offshore facilities declined considerably leaving the business unsustainable, and both yards sadly closed. Many members of the BarMac community went on to pursue further careers in the international fabrication business.